(Story)

m/c history

project

events

Hardware

Software

People

Media

Support

Future

Links-

The Project

So what is an ICT 1301 computer, and

why do we want to resurrect one anyway ?

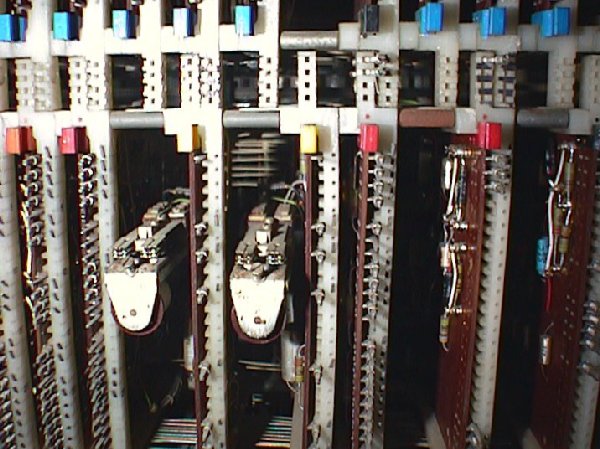

Because of about 150(ish) of these British Built and designed machines, which had their heyday in the early 1960's. This is the only machine left in the world, which in any way can be described as working. If this machine is not restored then there is little chance that either of the other remaining two 1301's in the world, will ever be restored. The machine represents a perfect example of a second-generation computer, which marks the move from valve technology to transistor based logic. It also defines the early use of Printed circuit Boards to implement the logic boards which are its building blocks and is also an example of the very early the use of Germanium transistors instead of the more common Silicon transistors in use today. However because the machine was designed to be dropped onto a factory or office floor, had little demand for its environment apart from limited air conditioning, and used relatively cheap industrial three-phase power, it proved popular. So popular that it represented at least fifteen percent of machine's made during the early 1960's,

Yes it's Older than BBC's Top Of the Pop's.

It also became the foundation stone of many software

systems that out survived the machine. It gave batch processing access to computing for a generation

that went on to design the world of computing today, which in turn gave rise to the internet and the

connected society which we all benefit from.

The software that was written during that phase is locked up in old 80 column punched

card packs and reels of non industry standard magnetic tape. If we can get the machine working to a

point where we can extract as much as possible from this library of software we may unlock parts of

that history and by using software emulators show what a 1960's computer is capable of.

We can also archive this data long term for future generations. The fact that we can even contemplate

this action is the result of a story of the life of the machine from its design in 1957(ish) to its initial

delivery to users, and its passing on from owner to owner. Each owner taking possession of the machine

for its scrap value, and by a succession of caring owners and I also believe, incredible luck,

the machine has survived in sufficient form for this project to be underway.

The Machine History

The London University Days

Authored by the Engineer

However the University was awaiting delivery of its computer and although not a final production machine, flossie was delivered to London University with a few design problems still unresolved. These problems were resolved one by one and each engineering change was implemented on flossie and her reliability improved remarkably. The result of this is that this was the very first machine of its type to be delivered to a customer’s floor and is why she represented the 'First' working example of her type.

So while Flossie continued to order supplies of pencils and allocate students to accommodation, the world moved on and eventually the day came when a faster and better computer was needed to do the work. Eventually the university ordered an ICL 1900 series computer and flossie was relocated within the computer area to make room and accommodate her replacement.

The question then arose about what to do with this now obsolete computer? ICT was only too willing to take the machine and clear the space for the University of London, after all they were buying a new machine. But that would have resulted in the machine being scrapped and the chain of events that gives us this machine today, started then. The university was approached by a group of students, who would remove the machine from london university and put it to use. This appealed to the University and the machine eventually exchanged hands for its value as scrap metal.

(The first time Flossie was Scrapped)

That group called itself Galdor, if the name rings a bell then just pick up a copy of Lord of the Rings, and start reading. I came to hear about this unusual event and after listening to reasoned argument from my fellow engineers I contacted Galdor to warn them of what they were about to take on. This was when I met two of the next owners of Flossie, in the Persons of Stuart Fyfe and Andy Keene. We met in a coffee bar in the ground floor of the Liverpool Victoria building just down from Russel Square, in the building above us was two working 1301's toiling away on 24hour shifts for the Liverpool Victoria Society. At that meeting I tried to dissuade these two young people from pursuing their project, and very fortunately, I failed. on the contrary they convinced me that they could, and would do it. So it was that I agreed to give a hand to the dismantling of the machine, in the hope that it stood a better chance of working again, if it was removed properly. I then realised that I had exposed myself to a problem, I was about to help a perfectly worthy group of students but my company may not have liked my involvement. It was for that reason that I stated my actions to my then manager, who took a kindly view and said if I was prepared to put my own time in for free and ensured that the area was cleared properly. Then he could see no problem, I was also to monitor the actions of the students and ensure no ICT test equipment was taken by accident and act as an ICT representative on site in accordance with any rules laid down by the University. I think my Company feared any taint of a large sale, by the actions of these students and I was the ICT watchdog for the removal weekend, acting unpaid of course. But I now had official approval, and a formal reason to be there when the machine was removed. The new owners first needed a place to hold the machine and one of the members of the group had access to a garage, so it was to be hauled away and I was informed later that they had 'Found' a real home for the machine. On the day of its removal I timeshared between waving the ICT flag in front of the client and trying to give help to the students, and boy did they work. Every thing was photographed, taken apart, marked and packed before going out the door. It was years later when I got into archaeology that I recognized the skill set they had used, and it worked well. Now I said earlier that the students had 'found' a home for the machine, well found is a pretty oblique word here, they had taken the lease on the garden at the rear of their property, cleared it and leveled it. laid a concrete base and topped it off with an industrial building large enough to house the machine ( almost ). It was a massive task and I was again very impressed with this group of people. So you can see that 'found' was just a bit of an understatement. Whilst this work was ongoing I stayed in touch with them and eventually, the machine had been moved to its new location, I next saw the machine when it was time for some fault removal. The most striking thing was the way they had shoe horned the machine into the building, the site was of a limited size and to allow access the printer has been skewed at an angle. Now this is something you can do if you are a private owner, and these improvisations and further modifications continued whilst the machine was with Galdor. Most of these gave additional facilities, and some made the machine easier to operate. The important thing is that most of these 'MODS' remain with the machine to this day. I did manage several trips to them and hopefully helped in their startup year, then unfortunately work overtook my free time and scare's from my employers about my activities and my security clearance at work, meant that I had to let my association with them slide. However I had letters from Galdor over the years stating what they had done, with a machine that had been sold as scrap. To further this contact, I had over the rest of my working years also met Galdor when our paths crossed in the course of my work and I knew that they in turn had also moved onto using 1900 series computers.

After retiring in May of 2000 I made several attempts to see what had happened to this machine. It seemed obvious that it had indeed been scrapped. Who would keep such a monster machine, and where? However there was a rumor that the machine had made it to the museum at bletchley. So I took the trip and as fascinating as Bletchley is ( and bletchley is very fascinating ) no sign of this old 1301 computer was to be found. I approached the British Computer Society, and asked if they had a list of machines which had been conserved. Some information was forthcoming, but no way of identifying this machine. Eventually I used the internet and found fellow staff that had also retired and also knew the 1301 machines well. I then started a private web site and by placing information about the 1301 machine's on the pages, I got all sorts of contact. Further clue's followed but it always seemed I had just missed an event or contact, but now I just had to know what had happened, there were far too many clues that the machine had changed hands again, and may still be in one piece. Then I hit lucky I found a reference to "Galdor", as a transition ( not a character from lord of the rings ) I also found a person who signed his emails with a specific message, and was able to find archived messages with this signature in. These two pieces of information gave me the contact I needed as I had found both Stuart Fyfe and Andy Keene once more, and I was totally overjoyed to discover that this same machine still existed. It had been passed from galdors hands into the hands of its new owner, again for its scrap value.

( the machine had been scrapped for the second time in it's life )

Again the machine had been dismantled, moved and reassembled. then due to circumstances beyond the owners control the machine had slowly languished over about twenty-five years. Now a machine of this age and sheer physical complexity is liable to develop faults over such a long time. So it was no surprise to find that when I contacted the owner, that the machine was very 'non functional'. But the owner had not just this machine but a whole set of spares, all it really needed was someone who wanted to help the owner and spend a little time resolving some of the problems. So over the winter of 200x we chatted by email and hatched a plan to try to see if we could get this machine back to working state again. Spring of 2003 saw the first visit and over the last three years we have made sufficient progress so that we are about 60 percent of the way to a working machine that can start to recover data from its magnetic tape library. Although we would like to finish the project an alternative if we fail, is to try to recover the software by digital extraction. This is a very expensive option for a purely voluntary project, and we need to try to complete the project the easy? way first. What we have learned along the way, is that there are a lot of people out there from New Zealand to Singapore to Europe and even more of them in UK who have stopped off on the internet to say they knew the 1301 computer's, wish us well and even in some cases help with parts/information/ and reminisces. The net result is that we out grew our old home. So ict1301.co.uk is the new home for this project. So visit us often, wish us well, come to an open day and be part of this project as we resurrect a part of British Computing History.

The Galdor Days

Authored by one of Flossie's Owners.

Notes from a talk by Stuart Fyfe at The Science Museum Thurs 20 Apr 2000

for The Computer Conservation Society.

The inserted thumbnails are of the slides used in the talk, click to see the full image.

Good afternoon.

I was sharing a flat, over a shop, with a couple of other students in Surbiton for Kingston

Polytechnic in the early 70's.

We did a load of weird student stuff - like the electric toilet flush that signalled to the world

when it was being used, and could be operated remotely for giving surprises; and the meccano rover

that ran up and down the pavement of the main road. Later, there was the model railway that ran

all round the flat. We thought it would be fun to buy a scrap computer to play with, and let schools,

researchers and ordinary people come and use it for their own projects.

At that time, "The Amateur Computer Club" was among the few national groups pursuing this new,

strange, hobby. They published hardware designs, and I had already made an adding-machine using

old Strowger telephone parts, but wanted something better, to really use.

We wanted to link it by telephone to an amateur astronomical observatory, with a big

telescope near Croydon. We looked at Elliot 802 with mercury delay line, and a PDP whatsit,

and got to know the surplus electronics trade, and the world of 5 track paper tape, but nothing

was quite right, not a proper machine.

( Web masters Note )

If I had known then, just what I was getting into, would I have still done it all?

( Oh YES! )

Just the job.

( Left ) = 1301 in Senate House, with 1904 Behind, and ( Right ) = front view of printer.

Apparently, we were only competing with scrap dealers for the price of the

metal, and the operations manager, Mr Hutt, was pleased to see it going for

educational use at the price of £200.

making coffee on the floor of the computer room

( Left ) = disconnecting processor bus bars and ( Right ) = Garage interior.

The last I heard of him, he was selling computers for ICL in Australia. It was a

tight squeeze, and there was a small heater to discourage condensation.

That house and garage has been demolished now.

It was just across the road from where Harry Seccombe lived.

I won't describe the tortuous search for premises, but we had noticed that

estates of war-time pre-fab houses were being dismantled.

You could get one of these for £200, delivered in sections.

It suddenly dawned on us that there was just enough room for one of these

in the back garden of our student flat, if we : Bought the lease, then

pulled down two derelict workshops, arrange planning consent, and barrow

a couple of lorry loads of concrete down the narrow passage that was the

only street access.

The best part, was the party for all our helpers and friends in the empty room.

The council had made us add an internal brick wall for soundproofing, and there

was a lot of fuss about obtaining three-phase mains.

( Left )= Street front of the Galdor Centre and ( Right ) = Console on the pavement, with hacksaw.

Others came to our flat or lived nearby, notably Dirk Koopman, Don Hedges,

Chris Hewitt, Adrian Barnes; and later Peter Singleton and John Skeene.

The name "Galdor" is a character in a book that I was reading:

Lord of the Rings by JRR Tolkein ... which was required reading for students.

A funny thing, we asked for an ordinary telephone line, and without prompting,

the number that we were given was 399 1300. I took this as a sign that we were doing something right.

Moving the machine to Surbiton in another tail-lift lorry was easy enough.

Except for one unit that was too wide for the passage way.

So we got out a hacksaw and attacked some runner extensions.

These runners were temporally attached to the main console - to stop it

falling over on its face. That was done outside, on the pavement, in the main shopping street, at midnight.

The most time consuming part of re-installation was, of course, re-connecting thousands of

wrapped wire links between the bays.

Andy, wiring

(That’s supposed to be a joke by the way).

Soldering made subsequent moving & re-assembly easier for the next owner.

We discovered that some corners are best connected by a left handed person, and others by right handed.

There's no risk of making a wrong connection, it's all 1 to 1 links. The design is ideal.

It's a lovely machine to work on.

rear of printer, plus Andy & deck 7

The triangle that this opened up allowed a convenient extension of the console work surface.

The first power on was not a success. No smoke, but the clock waveform was all over the place.

This derives, more or less, from simply amplifying a drum track.

We wanted to load some test programs, using an engineers trick,

whereby the card punch can be used as a card reader since it incorporates

a check-reading station that's normally used to verify the correct punching of holes.

The card punch made a horrid noise and jammed because the motor was rotating in the

wrong direction. All the motors were rotating in the wrong direction, including the drum.

The three phase mains was wrongly connected somewhere, although the colour sequence appeared right.

The fault was probably in the street, but easily fixed by swapping a couple of phases.

That fixed the clock, now we just had to find where the faulty circuit boards might be,

and anything else that wasn't working.

Fault finding was pretty easy because there are test points everywhere, in fact,

it's all test points. The diagrams are faultless and identify every pin and wire.

And the test programs are pretty good at identifying the problem areas.

A measure of ingenuity and imagination is still needed to translate the initial

symptoms into: which gate or board is faulty, and for me, that satisfying process of

deduction was what made the project so worthwhile - along with the things we used it for.

With multiple faults masking each other, it did take some months to commission the machine.

I remember the mechanical timing adjustments on the printer were particularly tedious.

But once it had settled down, there was a fresh fault only about once a month.

( Left ) = Console with cat and ( Right ) = Trevor wiring

Some sections were quite a puzzle, because it didn't go wrong often enough to let us

become fully familiar with the circuitry. It could take a day to pin down a subtle

fault in the tape system, but we would learn a lot by the end of it.

An oscilloscope and a voltmeter were the test tools. D.C. and 1MHz are easy to measure.

An operator sitting at the console could send specific signals, data values or operations

to most parts of the machine, at full speed, one instruction, or even single clock pulses,

and the effects be monitored on the gates by a colleague wheeling (demonstrate) this

enormous oscilloscope from one bay to another. Sitting with the diagrams open at the

console, one would call out things like "see if 8G27-5 goes high when I clear CR2".

And then, power-off, and whip out the faulty card.

Having wire wraps everywhere certainly slows things down, and it's worth making some additional tests

Rodney with hammer

( Web masters Note = Boy but that felt good ! )

This is an ideal, engineer-friendly, scale of machine. We replaced individual

faulty transistors when there were no spare circuit boards of the right type.

You couldn't do that with an integrated circuit, or even TTL logic.

printer index wheel

( Left ) Cutting cables and ( Right ) = Standing on frame + hacksaw

drum store

Adrian sitting at a desk card punch

One of these was in Glasgow and had quarter inch tapes which involved a two stage transfer via

London & Manchester Insurance’s mix of quarter and half inch tapes.

The 1302 had a 1900 type interface as standard, but as these systems had all been scrapped,

it was left to Galdor to convert the final tapes from several 1301 sites into 1900 format.

(Left) = IAS barn door and (Right) = Drum unit close up

The audience at The Science Museum looked horrified at our wrecking a quirky feature that

characterised the 1300 series, but relaxed when I continued with - It's all documented, and can

revert to sterling by operating a switch in one of the bays.

Modifications were always built properly in 1300 series technology wherever possible.

The switch selects binary, sterling or hex, not decimal. We hear that a similar approved

modification was installed on some other 1301s to treat the sterling commands as decimal plus a

patch in “initial orders” to check the current switch position.

We added a "56" (I think) instruction to index or modify other instructions, ie. it adds the

bottom 6 digits of the IAS location to CR2. This was a big help in many programs.

One practical change was adding some buttons on the console to clear an entire register in one go,

without having to dial up a lot of zeroes first.

This involved attaching diodes to the back of the dials to form simple pull-up gates. We got the

idea from the way the “initial orders” button works - it sets some zeroes and ones into the three

control registers to perform a drum transfer and jump. In principle, any frequently required number

could be entered this way by adding more buttons.

Some changes were made to the original fixed program "Initial Orders". This let the operator set

some manual indicators to do things like unload all the tapes, and a very big help was the invention

of the G card - When a program is being loaded from punched cards, the last card that is read is normally

an E or entry card, whereupon the processor stops and displays all-the-ones in CR1 waiting for the

operator to set the program running and it also displayed the program checksum so you could check it!

Well, if you overpunch the card's E with a 2, the modified Initial Orders only stops if the checksum is wrong.

It works because card code E has a numeric of 5 and G a numeric of 7.

To get the program to stop on loading all you had to do was push a chad

back into the 2 hole and rub it a bit with your thumb nail.

The modified I.O.s could also sumcheck regions of drum store, comparing a reference checksum punched on the

G card, and re-load the program from a library tape on magnetic tape deck 7 if the stored image was corrupt

or missing. This can save a lot of time when running a series of programs in sequence unattended, loading

each program from tape rather than cards. Only G cards and data need be put in the reader.

The ready light for deck 7 was changed for an illuminated push button, so we could put the library on-line

without walking across the room.

Another trick was improving the multi-tape file sort program by running a pre-pass of drum based record

sorting, processing the keys and pointers in IAS with a bubble sort that made a characteristic whooping

noise on the speaker. Small files could then be sorted entirely on the drum, and larger files on tape in

a fraction of the previous time. We never understood why such obvious things were not provided by ICL as

standard. My colleague Andrew Keene can take credit for much of this sort of trickery.

The loudspeaker gets a click each time a test-and-jump instruction succeeds. One gets to know the normal

and abnormal sounds of each program. Inevitably, several music programs were popular.

The original 1301 clock signal generator circuit was improved with a phase-locked loop that proved more

stable. I think it uses the 555 chip.

The 1301 1Mhz master clock signal is derived from the currently selected drum timing track via several

circuit boards of variable frequency oscillators and counters. Its ability to track the drum and produce

a good timing signal reliably was often questioned. The whole lot was replaced with an oscillator and

phase locked loop controller on a single IC that had recently become available. A few experiments showed

that it would happily work upside down with its ground strapped to the -6.5v rail, more to the point it

could track the drum at virtually any speed. The test being to turn the drum motor power off and see how

long your program carried on running.

( Left ) = Typewriter and ( Right ) = Card Reader.

It got quite hot sometimes, and I quite wanted to add an instruction that could be triggered by

temperature to release the door panels and flap them about a bit. As it was, we fitted a chimney or two

in the central units and a big extractor fan in the roof space. I wanted to get it to control the model

train that ran around our flat.

The commercial three phase electricity tariff gave us cheap power overnight, the main reason we ran at night

(apart from being students) was the temperature.

A nocturnal lifestyle suited us,

but confused our clients. We had occasional visits from The Amateur Computer Club and a few schools,

but most activity was with customers who appreciated our low overheads.

We wrote programs to look after club and society membership lists. It was called "Clubsoc" and used by

some 35 organisations eventually. Nowadays they'd probably do it all themselves with PCs, but in the

mid 70's a cheap bureau service was ideal. It started with London Village, and went on to include the

UK administration sections of Amnesty International and of Friends Of the Earth; Town and Country Planning

Association; National Council for Civil Liberties; the Legalise Cannabis Campaign and Vole Magazine to

name just a few. The data was punched from forms onto cards by a separate bureau, and we would produce

lists and mail-out labels, usually monthly.

Processing typically was reading punched cards onto magnetic tape, sorting the records into member number

order, merging these transactions with the main tape file, and printing various reports and lists, mostly

in an automated sequence. Records for resigning members were not deleted immediately but were carried

forward for one generation to the new master tape, so that all the reports including deletions could be

printed from the same tape.

We also produced printed bio-rhythm charts for a client, and later on, processed the complex administration

for the Southern Counties Cat Fanciers shows.

console and me standing

We provided standby processing for other ICL sites, and did a 6 month period of continuous contract

operating in two12 hour shifts at Liverpool Victoria Friendly Society. Their machines

were "Samantha" and "Arthur", which suffered a form of Y2K crisis when insurance interest rates reached

10 percent, suddenly needing 2 digits. We also used the G card, and persuaded them that Initial Orders

always had this ability, but they were not so sure about the origins of the ability to run a sequence of

programs from tape unattended. We did enough like this to keep the business running, and kept on buying

scrap machines, progressing through the 1900 series, - which contained useful amounts of reclaimable gold.

We used Cobol and George 3 and moved to bigger premises. I left Galdor when the fun went out of it, and

now I provide software support for veterinary surgeons, and am looking for more work if anyone's listening.

In conclusion, the 1301 is of a size where it feels just possible that one could get to know

everything about it, hardware and software, including time sharing. Somehow, that's important.

It feels uncomfortable using modern PCs and stuff, where one only has the roughest idea of what it's up to.

I can see in the audience, some of the people from Galdor. Perhaps they would fill us in with anything

that I've missed.

We handed on the machine in June 1977 when the space was needed for other things, and the next speaker,

Roger Holmes, will take up the story. Working around "Flossie" was one of the most satisfying things

I've done, and much credit goes to the designers.

Thank you.

Copyright Stuart Fyfe April 2000

The Last 30 Years

This section Authored by the Current Owner

( who calls himself, quite rightly ) Flossie's Custodian.

Part 1

I visited Galdor in Surbiton to see what a 1301 was like, and met Stuart Fyfe and Andy Keene.

Strangely my main memories of that meeting are my surprise that the pet cat was not only allowed

into the computer room, but had taken up almost permanent residence on top of the power stabiliser

rack, and that they had the first electrically flushed toilet I had ever seen. I was shown the

inside of the CPU, and I was a little worried about the machine’s speed when I spotted some relays.

It was quickly explained that these only had to work at human speeds, as they merely controlled

the manual setting of values into registers.

Part 2

I ended up buying Galdor's own machine, spares, manuals, software and technical drawings.

Transportation cost more than the machine itself. We had problems with the transit castors

on the units bending their attachment bolts. The castors on the magnetic tape units had brittle

plastic tyres which broke up at the slightest bump and then on each revolution of the castor,

the unit had to be rocked. The real problem was when more than one adjacent castor failed on a unit,

it took four of us to manhandle it back onto its castors every few feet.

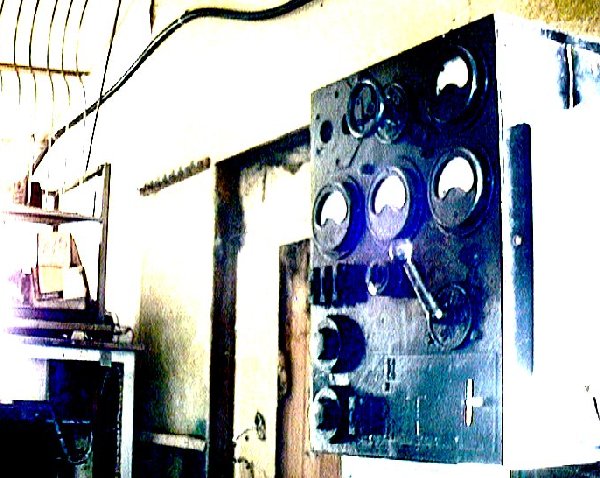

I was still aching the next morning, but full of enthusiasm. I opened the door but could not get in because the room was full of computer units. I got a step ladder, climbed on top and surveyed what I had bought, stepping from unit to unit five feet up in the air. I did find a small space about four feet square and realised what I was dealing with was like one of those kids puzzles with plastic tiles in a frame you slide around until you get them in the right order to complete the picture. After much shoving I got one of the units I was going to dismantle for spares next to the door, and the gap the other side. I collected my tools, dropped down into the gap and started dismantling. And so we gradually made enough space to reassemble Flossie. With a little help from my brother and a couple of friends, I made reasonable progress, considering I also have a full time job. The logic connections between racks of 1301s were normally made with wire wrap joints, and the main task in recommissioning them is wrapping these thousands of joints. With Flossie, Galdor had soldered all these joints, and when we dismantled her we unsoldered one end, so that for reassembly we only had to resolder one end, although we did have the problem of solder dripping onto the joint beneath, so we quickly learned to start at the top and work downwards to avoid solder bridges. We had managed to remove Flossie without separating the two main CPU racks, so this saved a lot of soldering. The 1301 uses a three phase electrical supply, but the farm where I live had only a single phase supply, indeed there were only two wires to the transformer on the pole in the field. The electricity board wanted, strangely, £1300 to bring in a three phase supply on a series of poles from a different direction. It was the ruining of a nice view which put me off this mainly. I looked around for a cheap 10KVA three phase generator and eventually found one for £400 from the owner of a Thames sailing barge moored in Faversham creek.

It was not ideal - built in 1936 or a little later by Tangyes- Ricardo, 3.5 litre twin cylinder diesel with hand start, and extremely heavy. It had seen service with the RAF and later had powered the lights at the White City dog track. Despite being practically antique, this has given sterling service, both for the 1301 and through many power cuts and after the 1987 great storm when we were without mains power for ten days. The only major problem was that the control unit suffered vibrations from the engine, so I lengthened some of the cables and brought it indoors.

One winter I failed to fully drain the radiator, and the bottom section froze up. Fortunately one of my friends got the aluminium welded by his brother who worked for Woolwich college. He also made a new cylinder head gasket from a sheet of copper. We later got our mains supply cables upgraded to three phase and so now Flossie is almost always run from the mains.

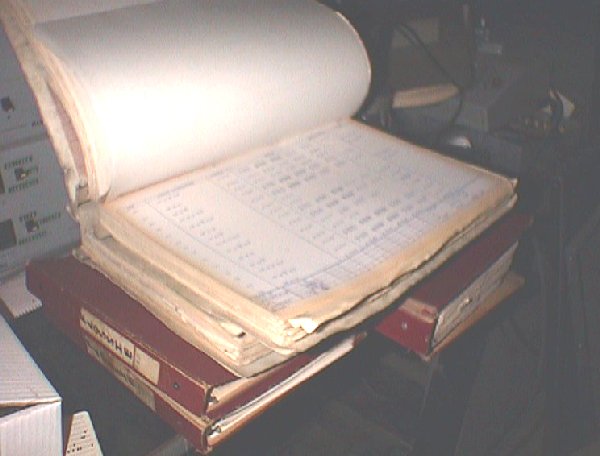

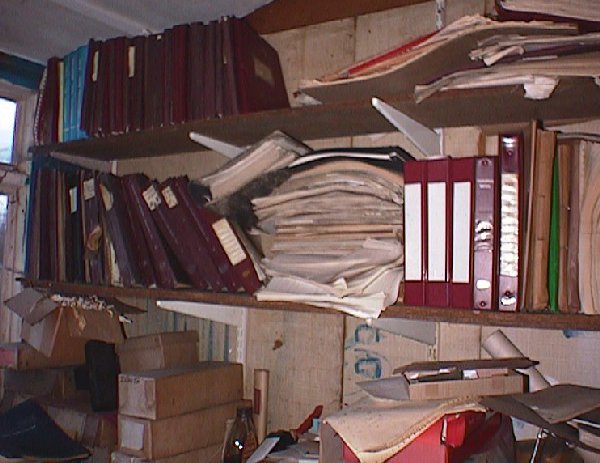

My Computer Science degree course did contain a section on Boolean arithmetic, and some of the theory of logic design, but at computer maintenance I was a complete novice. I could not even solder properly, and as for tracing logic faults, I just applied similar principals to debugging software. I learnt a great deal very quickly and I think this indirectly helped my career greatly. A couple of years later I pointed out to one Marconi’s hardware designers how to simplify the connection between a microprocessor and its memory management unit, and he came back later and said I had saved about 40% of the components of the CPU board! A year after that I designed an interface cards for Apple ][ computers, of which my company sold over a thousand, and other designs followed that. Back to the 1970s and we had Flossie's basic units connected up and we followed the instructions - turn on and check for smoke. There was none and so we stated running through a progressively more complex series of tests called the ‘Prototype Test Programs’ published by GEC Telephones of Coventry, one of the partners in the project which produced the 1300 series. Flossie's CPU was most likely built in Coventry, and the peripherals by ICT, maybe in London. When fault finding the hardware, the Field Engineering Manual gets used a great deal. So much so that the edges get frayed the folds wear out and the spine has broken, and time has to be spent repairing the manual before repairing the computer.

These are constant companions when fault finding on the machine, but there is much more documentation received with the machines, this shows about a third of it.

I spent a great deal of time just identifying which parts I needed to read and trying to remember what manuals had what in them. The field change notices made interesting reading. Things like - strip out 1/4 inch earth connections and replace with half inch copper braid - then later - strip out half inch copper braid and fit one inch copper braid. When working on the machines you very soon appreciate the very high quality of the engineering.

Even the main framework of the machines are incredibly well built. This picture is a bit extreme, but it shows a bare frame which has been scrapped, has stood outside for twenty years, one end buried in the soil, but apart from some light surface rust looks nearly as it did when I left it there. The frames are heavy angle section welded very accurately, with hundreds of tapped and plain holes drill at precise locations. Down the centre of a rack runs the space wiring, the high speed signals carried on parallel wires running at least a quarter of an inch apart, though they have been removed from this scrap unit. This is a double rack and so has four bays - two one each side. I find it ironic that most companies making mainframe and mini computers, and even modern servers and network hubs, use 19 inch telephone racks, whereas the telephone company who built the 1300 series electronics designed custom built racks for the job. I had at first thought that I could use just my trusty AVO meter to identify faults but I soon realized I had to spend some money on an oscilloscope. The best I could find in my price range was an old valve based EMI 'scope with delay facility, up to 40MHz and a twin trace plug in unit. With it I fixed a number of wiring faults, and some logic faults, some of which may have been caused by the wiring faults, some by the dust and vibration the machine endured whilst being moved, and some probably by its new diet of unstable generator 3 phase, especially whenever the generator slowed down and stopped due to running out of diesel. Eventually after much work Flossie ran its test programs successfully once more and we celebrated by running some music software on her.

Now you have read the history of this machine click the link below to start to follow

the progress on the current project